Aluminium Alloy Powder 5056

Brand jie han

Product origin shan dong

Delivery time 1week

It is often used in the construction of bridges, boats, ships and other structures due to its corrosion resistance and heat resistance.

Aluminum 5056 finds use as structural components in bridges, ships, aircraft etc., where low weight and long-term performance.

Download

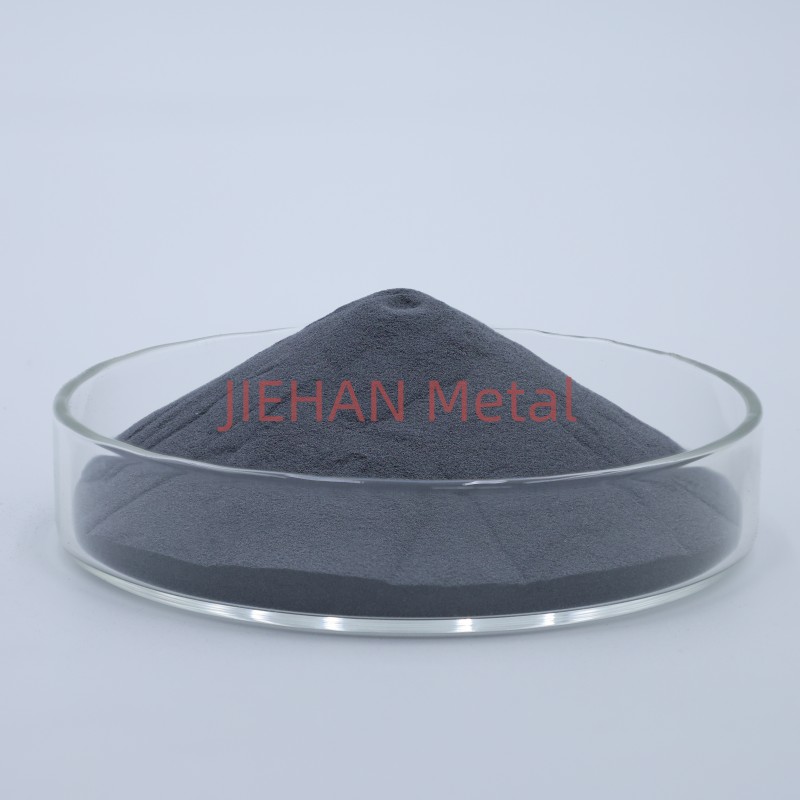

Product name: 5056 Atomized Aluminum Alloy Powder(Al-Mg alloy)

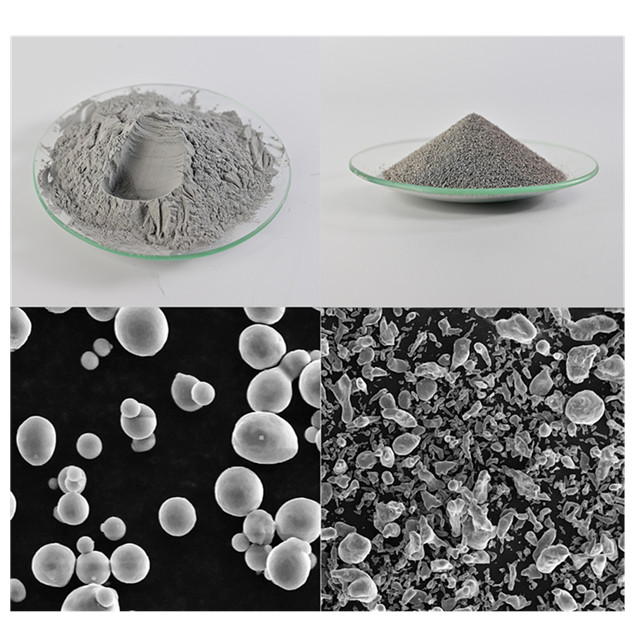

Appearance: Atomized Gray Powder

Producing technology: Nitrogen Protecting Atomizing Technology;

Advantages: Good particle size distribution, strictly produced from the raw material of 5056 aluminum alloy ingot, different particle size can be customized to be produced, 100g free sample can be provided for testing.

Application:

1. Raw material of powder metallurgy industry.

2. Raw material of MIM and 3D printing.

3. Metal additive for chemical industry.

Aluminium 5056 is an alloy of aluminum-magnesium with a high strength-to-weight ratio. It is often used in the construction of bridges, boats, ships and other structures due to its corrosion resistance and heat resistance. This article will provide an overview of aluminum 5056 compositions, physical properties, mechanical properties, and uses, as well as machining and welding info.

5056 Aluminium Composition

UNS A95056 is an alloy composed mainly of aluminum (95%) and magnesium (4%). It contains a maximum of 0.25% copper and 0.20% chromium for superior corrosion resistance. The alloy also contains manganese in small quantities to improve its strength and durability.

5056 Aluminium Physical Properties

The physical properties of aluminum 5056 are impressive compared to other alloys in its class. The alloy has a density of 2.7 g/cm3 which makes it significantly lighter than steel. It has a melting point range between 500°C – 630°C, depending on the composition, and can reach temperatures up to 400°C without damage or distortion due to expansion or contraction. The thermal conductivity is good at 167 W/mK, while the electrical conductivity is excellent at 30 MS/m at 20 °C.

5056 Aluminium Mechanical Properties

Aluminum 5056 has excellent mechanical properties that make it highly desirable for many applications such as bridges, boats, ships and more due to its high strength-to-weight ratio combined with good ductility and toughness, making it resistant to fatigue cracking even under cyclic loading conditions. It has a yield strength of 300 MPa with an ultimate tensile strength of 366 MPa which can be increased by cold working or heat treatment processes like quenching or tempering, which increases hardness but decreases ductility.

5056 Aluminium Uses

Due to its excellent corrosion resistance and heat resistance combined with lightweight properties, Aluminum 5056 finds use as structural components in bridges, ships, aircraft etc., where low weight and long-term performance are both important requirements for successful application performance over long periods of time without significant maintenance costs or downtime from regular inspections or repairs resulting from corrosion damage or other factors related to environmental exposure such as saltwater air from coastal locations etc., Additionally aluminium50 56 finds extensive use in the transportation industry such as bus body frames and boat panels due to its superior corrosion resistance when compared with steel alloys commonly used for similar applications.

Corrosion Resistance

Of all the grades of aluminum, few can compete with 5056 when it comes to corrosion resistance. This grade has repeatedly proven its strength in harsh environments and can even resist saltwater corrosion. Its superior structural integrity makes it ideal for outdoor applications, and it is often used in products that are exposed to a wide range of weather conditions. Additionally, its low weight makes it a popular choice among fabricators looking for an aluminum alternative that doesn’t add additional strain on construction materials. If you’re looking for superior corrosion resistance that won’t weigh you down, then 5056 Aluminum is a perfect choice.

Heat Resistance

Aluminium 5056 is a popular choice for industrial applications because of its remarkable heat resistance. It has a higher strength-to-weight ratio than other aluminium alloys, making it ideal for heavy-duty applications that require superior corrosion resistance and heat resistance. The alloy also features the highest ductility and resilience when exposed to elevated temperatures, making it perfect for operations taking place in high-temperature settings such as air space sectors or power plants. Aluminium 5056 is one of the few materials that can consistently and reliably perform under extreme temperatures without significant ageing, wear or buffering. In short, this versatile material is essential for industries that deal with the heat on a frequent basis.

| Certificate of Analysis | |||||||||||

| Product Identity | |||||||||||

| Product Name | 5056Aluminum Alloy Powder | ||||||||||

| Specification | D50=6.992um D50=14.97um D50=21.64um | ||||||||||

| Batch No. | 20180508 | ||||||||||

| Production Date | 2018.03.22 | ||||||||||

| N.W. | 9KG | ||||||||||

| Particle size | D10 | D50 | D90 | ||||||||

| 3.514um | 6.992um | 11.84um | |||||||||

| 2.192um | 14.97um | 32.22um | |||||||||

| 2.192um | 21.64um | 43.02um | |||||||||

| Testing Result | |||||||||||

| No. | Testing Items | Testing Result(%) | Rrange(%) | ||||||||

| 1 | Al(%) | 93.710 | Balance | ||||||||

| 2 | Mg(%) | 4.280 | 4.5~5.6 | ||||||||

| 3 | Mn(%) | 0.091 | 0.05~0.20 | ||||||||

| 4 | Fe(%) | 0.231 | <0.4 | ||||||||

| 5 | Cu(%) | 0.040 | <0.1 | ||||||||

| 6 | Si(%) | 0.170 | <0.3 | ||||||||

| 7 | Zn(%) | 0.050 | <0.1 | ||||||||

| 8 | others | 0.100 | ≤0.15 | ||||||||