High Strength AlMgSc Alloy Powder for 3D Printing

Brand Jie han

Product origin Shan dong

Delivery time 1week

Supply capacity 100 ton per month

High Strength AlMgSc Alloy Powder for 3D Printing

advantages:1. Particle size D50 can be customized from 1-10 micron to 300 micron.

2. Atomized producing technology with high purity.

Download

3D Printing High Strength AlMgSc Alloy Powder

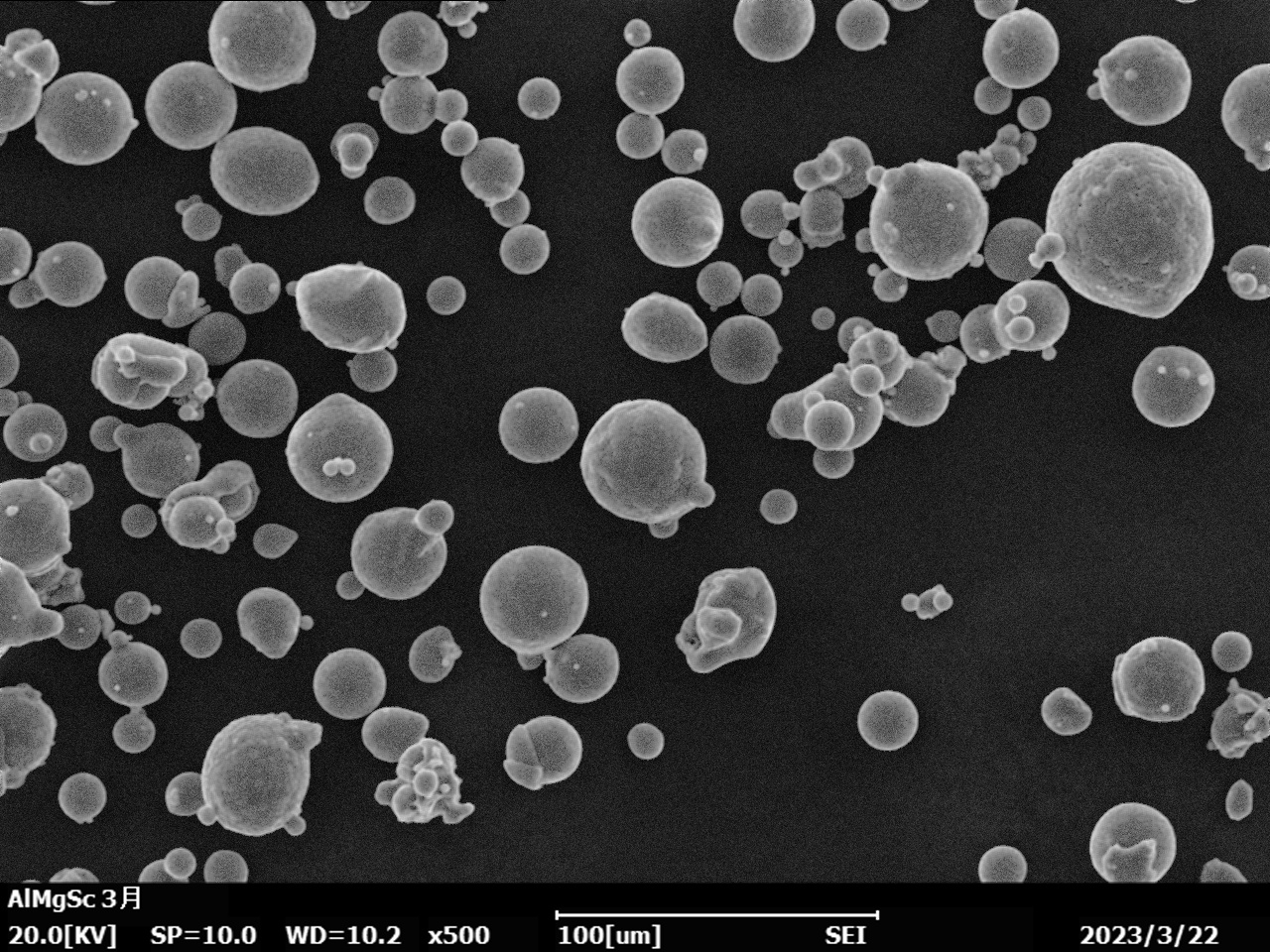

Production Technology: Vacuum Induction Melting Gas Atomization (VIGA)

Morphology: Spheroid.

Particle Size: 14-45um,15-53um,20-63um,63-106um, etc. Different particle size from 1-10 micron to 300 micron can be made customization according to your good requirements.

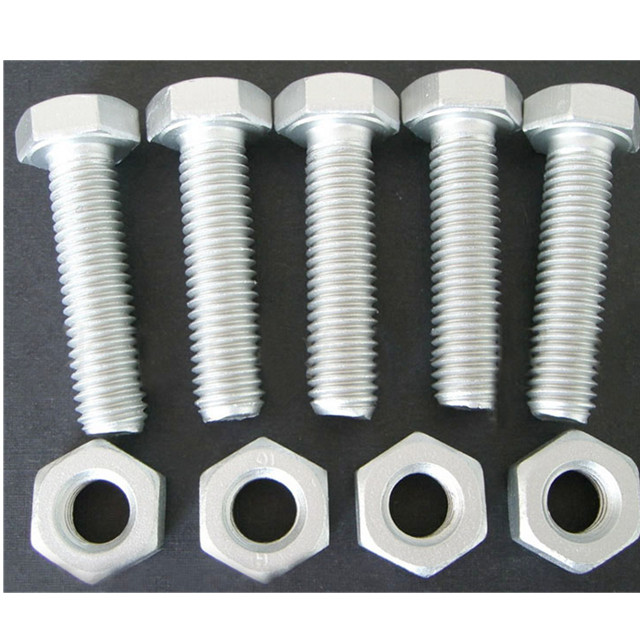

Application:3D Printing for light-weight or bracket structural parts and heat dissipation components used in the aerospace or automotive industries, MIM industrials.

Advantages: Lower rate of hollow powder, good fluidity and sphericity with higher bulk density.The AM parts have ability on corrosion resistance, lower density and higher mechanical strength, less requirements for heat treatment comparing to the casting parts.

Packaging: Congrugated cardboard box/Aluminum foil bag/Plastic bottle/Steel barrel/ or diiferent kinds of packing type can be customized, vacuum packing is available.

Physical Nature | ||||||

Size | Yield Strength (Mpa) | Tensile Strength (Mpa) | Elongation % | |||

Non Heat Treating | Heat Treating | Non Heat Treating | Heat Treating | Non Heat Treating | Heat Treating | |

15-53μm | ≥310 | ≥500 | ≥400 | ≥535 | ≥15 | ≥10 |