Characteristics of different types of Aluminium paste

Characteristics of different types of Aluminium paste

According to the arrangement and distribution, aluminum paste is mainly divided into leafing aluminum paste and non-leafing aluminum paste. SHAN DONG JIE HAN METAL MATERIAL CO.,LTD. is a professional manufacturer of aluminum pigments in China.

Leafing aluminum paste means that the aluminum pigment is flowing on the surface coating, arranged neatly and can show excellent metal effect, even achieving the electroplating effect, high brightness, strong corrosion resistance, but frankly speaking, its adhesion is weaker than non leafing grade and it is not easy to color.

Non-leafing aluminum paste means that the aluminum pigment is distributed in the middle and lower part of the entire coating, arranged in messy way, and will show a "different angle color" metal effect, strong adhesion, and easy to color. But the metallic feel is weaker than leafing pigments.

According to the production process of aluminum paste, it is mainly divided into corn flake aluminum paste , high sparkle silver and electro-plating grade.

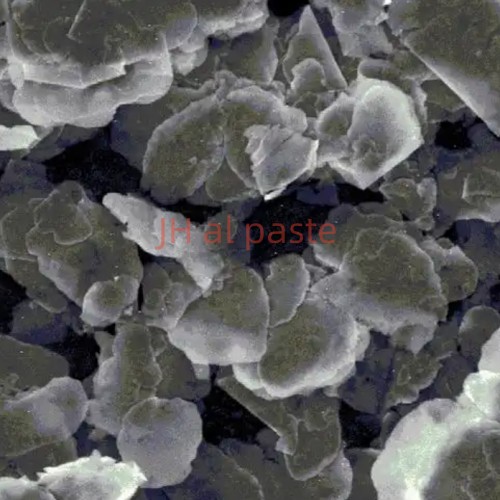

Corn flake aluminum paste: This series aluminum sheet is smashed by steel ball, and then ball-milled again until the aluminum sheet diameter is broken (aluminum is originally in sheet form), and then grounding, aluminum material has ductility, and high hiding power. The characteristics of flake aluminum paste are week metallic and high hiding power. The particle size is generally below 12u.

Silver dollar electroplating: through ball mill grinding, and open its sheet diameter to grind out the metal effects without smashing or destroying the structure of the aluminum itself. The general characteristic of silver dollar shape electroplating aluminum paste is that it has strong metallic effects but it is much long time produce. The series particle size is generally below 12um.

High sparkle aluminum paste: The process is easier than electroplating and fine silver processes, and the effect is shiny sparkle. The particle size is between 15um to 65um.

After we have a general understanding of the basic concept of aluminum silver paste, we turns to its properties. It mainly involves metal effects, hiding power, adhesion, stability, dispersibility and other characteristics in different industries.

Metallic feel: the appearance of aluminum paste;

Hiding power: the tightness of the arrangement of aluminum flakes, whether the substrate can be covered with the least amount of addition;

Adhesion: whether the silver paste can be well wrapped in the resin system without losing silver;

Stability: whether the aluminum paste coating system can not react to ensure a long service life;

Dispersion: whether the aluminum paste can be well diluted without settling and agglomeration:

Of course, the above are just some common properties. There are different test indicators for each industry. For example, the glass paint needs to have good alcohol resistance, and the printing needs to be washable, etc.

Finally we talk about the water-based aluminum paste industry that has emerged in recent years. In the past, aluminum paste was not divided into water-based and solvent -based. However, with the continuous development of society, people pay more and more attention to environmental protection, and solvent aluminum paste would emits of VOCs to pollute the environment, so the call for environmentally friendly aluminum paste is getting higher and higher, which has given rise to the research and development and production of water-based aluminum paste. Water-based aluminum silver paste has become increasingly competitive in the market due to its extremely low VOCs emissions and the safety of production and use. With the increasing emphasis on environmental protection, it is believed that more and more paint manufacturers will invest in the research and development of water-based paints, and the spring of water-based aluminum silver paste has arrived. silver aluminium paste that is more compatible with the resin and more suitable for your own system.