Basic Introduction of Aluminium pigments

Introduction of Aluminium pigments

Aluminum paste belongs to chemical industry -> fine chemicals -> inorganic pigments -> metal pigments, and metal pigments can be divided into two categories, that is copper pigments and aluminum pigments. Copper pigments are what we usually call copper gold powder/gold paste, and the other is aluminum pigment which is our mainly introduction today, aluminum paste.

Before introducing aluminum paste, we must first have a basic information, that is, what is the difference between pigments and dyes? Dyes are colored organic compounds that are generally soluble in water or organic matter, or some insoluble dyes are converted into a dispersed state by chemical means to promote dissolution. Pigments are different. They are insoluble colored compounds that are generally insoluble in water, oil and solvents, but can be evenly dispersed in solvents. In generally, pigments exist in the solvent in the form of particles, while dyes exist in the solvent in the form of molecules.

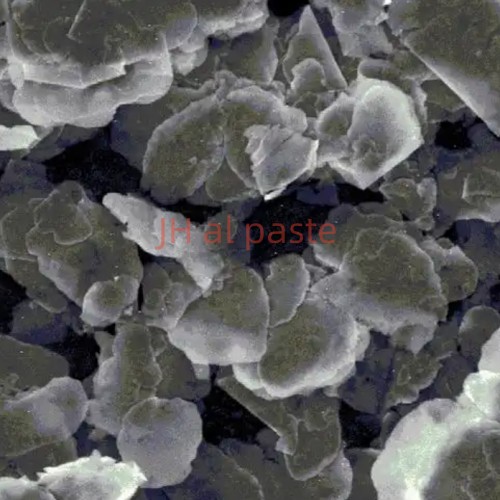

In the huge family of pigments, there is a most "shining and dazzling" member - aluminum paste. The reason why it is called aluminum paste is that it is mainly composed of aluminum flakes and solvents, and is in a paste state. After being processed by a special treatment process, the surface is smooth and flat, showing a silver metallic luster, so people call it aluminum paste.

Shape and distribution of aluminum paste under microscope.

According to the arrangement and distribution of aluminum in aluminum paste, it is mainly divided into Leafing aluminum paste and non-leafing aluminum paste.

Leafing aluminum paste means that the aluminum pigment is distributed on the top ofcoating, arranged neatly and can show an excellent metal effect, achieving the effect of imitating electroplating, high brightness, and strong corrosion resistance, but relatively speaking, its adhesion power is weak and it is not easy to color.

Non-leafing aluminum paste means that the aluminum pigment is distributed in the middle and lower part of the coating, arranged in a messy manner, and will show "angular variation" metal effect, with strong adhesion and easy coloring. But the metallic feel is weaker than Leafing type.

In the next section, we will provide a detailed introduction from the manufacturing technique and performance of aluminum paste.