Machine for Air Atomized Aluminum Powder

Brand Jie Han

Product origin Shandong Province

Delivery time 20 weeks

Supply capacity 5 set /year

The Machine for Air Atomized Aluminum Powder is widely used in the fields of pigment like plastic, rubber, adhesive, macromolecule materials, high polymer composite, functional materials and so on; It can not only improve the compatibility of both non-organic mineral stuff and organic high polymer, enhance binding force of interfaces, rise the mechanical strength and comprehensive ability, but also increase the stuffing ability of powder, save product cost as well.

Download

Aluminum powder is classified with fireworks aluminum powder, coating aluminum powder, atomized aluminum powder, AAC aluminum powder and metal effect aluminum powder.

The Machine for Air Atomized Aluminum Powder is widely used in the fields of pigment like plastic, rubber, adhesive, macromolecule materials, high polymer composite, functional materials and so on; It can not only improve the compatibility of both non-organic mineral stuff and organic high polymer, enhance binding force of interfaces, rise the mechanical strength and comprehensive ability, but also increase the stuffing ability of powder, save product cost as well.

They can be used in a lot of industries such as explosive, fireproof steel, firework, fire resistant material, anti-corrosive materials, autos, welding, Autoclave Aerated Concrete Blocks and etc. Aluminum powder also plays an important role in construction, electric, chemical and national defense industrial. For fine aluminum powder can be used in military industries. Atomized aluminum powder produced by the U.S. has been following under the requirements of MIL-A-239DA (AS) . In China, the aluminum powder producer implement the standard of GJB1738-1993.

Section 2 Basis of Design

The seller should be provide the technical requirements of air atomized aluminum powder.

Sinopec Group SHSG-052-2003 "petrochemical plant process design package (complete technology process package)

Technology sources and authorization

This design package includes technology of air atomized aluminum powder and operating parameters; Aluminum multi-stage air classifier process and operating parameters are technical know-how of technology providers. The proprietary technology of all intellectual property rights owned technology provider, the transfer-er got the right to use this technical know-how. Enterprise of engineering construction and of design have responsibility tokeep technical secrets, and shall not disclose to third parties or the transfer to others.

Referring to military standard GB/T2085.1-2007 of People's Republic of China

Grade | Active aluminium %MIN | Size mesh |

6210 | 96-98 | 12-36 |

6211 | 96-98 | 36-55 |

6212 | 96-98 | 55-80 |

6213 | 96-98 | 80-100 |

6214 | 96-98 | 100-120 |

6215 | 96-98 | 120-150 |

6216 | 96-98 | 150-180 |

6217 | 96-98 | 180-200 |

6218 | 96-98 | 200-280 |

6219 | 96-98 | 280-300 |

6220 | 96-98 | 300-325 |

Process flow description

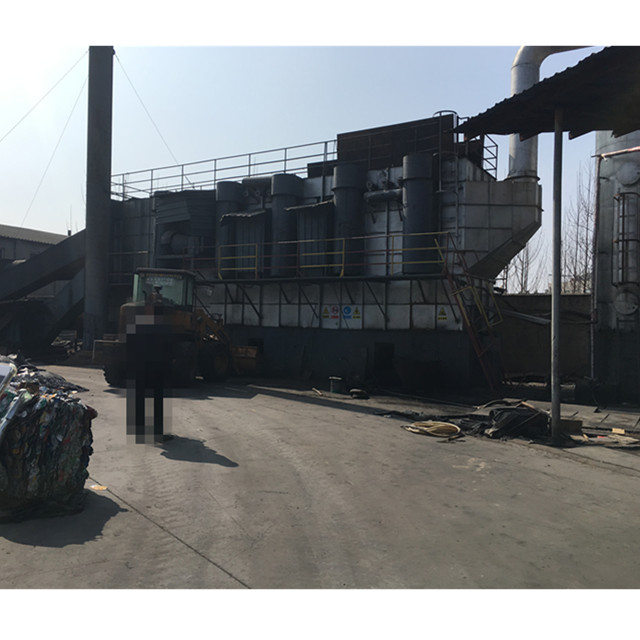

Aluminum ingot melting

Qualified aluminum ingots removed surface dirty by damp cloth or brush, naturally dry and reserve. Transported to feeding steel platform that in the melting furnace by forklift. Aluminum ingots will melting in furnace after preheating stage, melted aluminum liquid into the holding furnace through launder by hydraulic dumping devices, the aluminum liquid continue heated and maintained at a specified atomization temperature in holding furnace, according situations to remove impurities by refining, slag skimming before atomization. The liquid aluminum of the nozzle into the spray chamber after extracted and crushed to small droplets by heating air from atomizer.

Aluminum melting furnace installation to ensure that the hydraulic rose to the highest, the lowest level higher than the holding furnace minimum level, aluminum liquid empty in melting furnace. The tilt system of holding furnace controlled by hydraulic system, the hydraulic system move to the up/down and forward/backward. Hot exhaust gas through the pipeline into the atmosphere after combustion by induced draft.