THE WIDE APPLICATION OF ALUMINUM SILVER POWDER

THE WIDE APPLICATION OF ALUMINUM SILVER POWDER

First, aluminum powder because of its silver-white metallic luster, so commonly known as aluminum silver powder or silver powder, its chemical composition is actually "aluminum", not "silver". Application: powder coating, ink, plastic masterbatch, printing, imitation gold paper, imitation gold card, gold film, textiles, but in water-based paint and paint with acid and alkali will be oxidized black. Not recommended for applications requiring acid and alkali resistance and combination with rain.

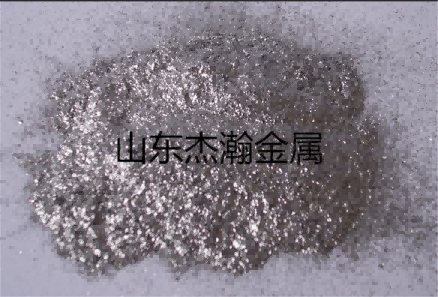

Second, ultrafine silver powder: 1, ultrafine silver surface area is large, when it is exposed to the air, can quickly generate a layer of passive protective film on its surface, that is, oxidation black, need to do a good job of sealing measures. 2. The larger the amount of silver powder added, the more white, the smaller the amount added, the more blue, the less the amount added, the black spots and black silk, the overall black. 3, the floating silver is flake, always floating in the outer layer of the coating, so the hardness and anti-oxidation blackening performance is slightly poor, to get a better hardness need to add anti-printing hardening agent, plus silver powder hardening agent, etc., can not add high gloss wax, gold and silver powder arrangement agent, polyethylene wax, etc., the longer the mixing time, the better the effect.

Third, 1, the smaller the particle size of silver powder, the stronger the metallic feeling, the stronger the hiding power. No matter how much silver powder is added, it can be evenly dispersed without black spots, and the effect of gray black, blue phase and different shades of silver powder can be modulated by adjusting the background color and reducing the amount of silver powder. The addition amount is very small, and the convection has a good promotion effect. 2, the flake structure of the floating aluminum powder will be destroyed (deformed or crushed) during the grinding and extrusion process, resulting in gray color, so the dry mixing method is generally used.

Four,non-leafing silver: 1, non-floating silver evenly and parallel distributed in the entire film, so it is covered by resin, so it has good oxidation resistance and wear resistance, good weather resistance to acid and alkali, no handprints, bright surface. 2, aluminum powder is especially suitable for outdoor products, because of the inorganic coating layer, with good water resistance, weather resistance, chemical resistance. 3. The addition amount of cover is tested with transparent base powder, and the addition amount of flash silver can reach up to about 10%; Mixing and spraying process directly affect the spraying and hiding effect, the larger the particle size, the better the flicker effect. 4, aluminum powder can withstand high temperature 600 degrees without discoloration.