Aluminum Powder Production Line

1. Profile

1.1 Taking the atomized aluminum powder as the raw material, ball milled aluminum powder is produced under the protection of nitrogen, with the method of impacting and grinding through ball milling medium in the ball miller. According to the different application, the ball milled aluminum powder can be categorized as aluminum powder for coating,flammable use (military), A.A.C. block and fireworks and firecrackers.

1.2 Named as metal gunpowder, the ball milled aluminum powder is flammable and explosive product, which was classified as the first class fireproofing and the second class anti-explosive product in the national regulation of fireproofing and anti-explosive. So we should progress the project according the national standard regulation, regardless of factory designing, equipments selecting and the product producing, using and processing.

1.3 Using the nitrogen as the protective gas, which being made as the method as carbon molecular sieve pressure swing absorption producing method, the modern ball milling system can be confirmed being in safety and stable operation.

1.4 In this project, we will take the cone and energy saving ball milling machine as the main machines, when in necessary, the frequency conversion speed regulation equipments can be matched. Compared with other general ball millers, the energy conversation can reach up to 20%-25% for this kind of ball miller, this kind of equipments can easily improve the product quality, especially for producing aluminum powder in different applications. What's more, cooling lubricating system is matched in the main axis of the ball miller, with better cooling effect, it can easily prevent the overheat of the bearings and improve the equipment operating efficiency.

1.5 This system uses adjusting cyclone separator, with adjusting the height of adjusting rod, it can adjust the product size distribution, which can meet customers’ requirements for premium quality products. However, with different products requirements, you can also use the MS micron grading machine produced by Hosokawa Japan as the separating equipment.

1.6 In this designing, phosphorus oxygen analysis meter is replaced by intelligent nitrogen analysis meter, which can not only save the investing cost, but also make this system more easily operating and maintaining.

1.7 Adding one more equipment as tail gas with dust collecting equipment on nitrogen exhaust pipe that can collect about 6-8MT finished powder, which can prevent the powder wasting and dust polluting. This can meet to the national environment protection regulation and guarantee the staff health.

1.8 The advanced vacuum transporting equipments, inclosed storage bin and quantitative variable frequency adjusting feeding equipments will be used in raw material transporting, storage and raw material feeding system, this system can change the disadvantages of elevator feeding system(which causes the powder or dust pollution) and raw material feeding with un-quantitative method. This good system can be cost saving and environment friendly, as well as easily operating and controlling for product quality and system stable.

1.9 We will use two big size ball millers with Φ1830mm×3000mm in this system, it is the biggest scale or output mill.

1.10 For this system, through adjusting the ball milling medium allocation, it can produce the premium coating used aluminum powder, gas developing aluminum powder, flammable micron aluminum powder, pesticide used aluminum powder, fireworks used aluminum powder and the like. so in this system, the used equipments instruments and meters, can be easily maintained and operated, at the same time, the cost saving advantages, high efficiency and energy saving characters make it as the state of the art within domestic of China.

Designed output: aluminum powder for fireworks and firecrackers about 800MT per year, aluminum powder for coating and pigments about 1066MT per year, aluminum powder for A.A.C block about 1500MT per year, aluminum powder for pesticide and military about 3000MT per year.

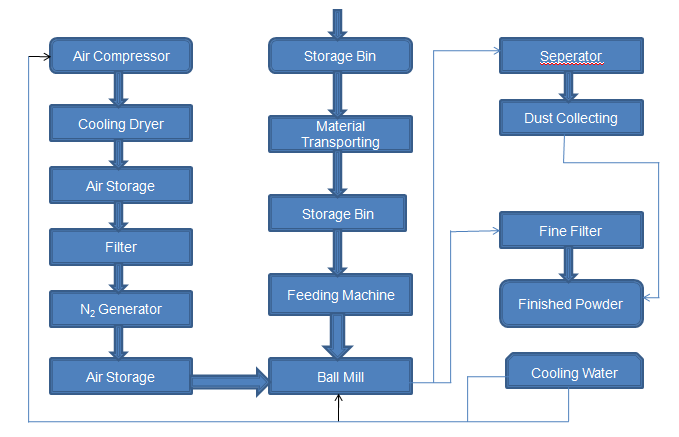

2. Technology and process flow.

2.1 Process flow diagram

Please kindly refer to the following diagram.

Atomized aluminum powder +3.5% stearic acid